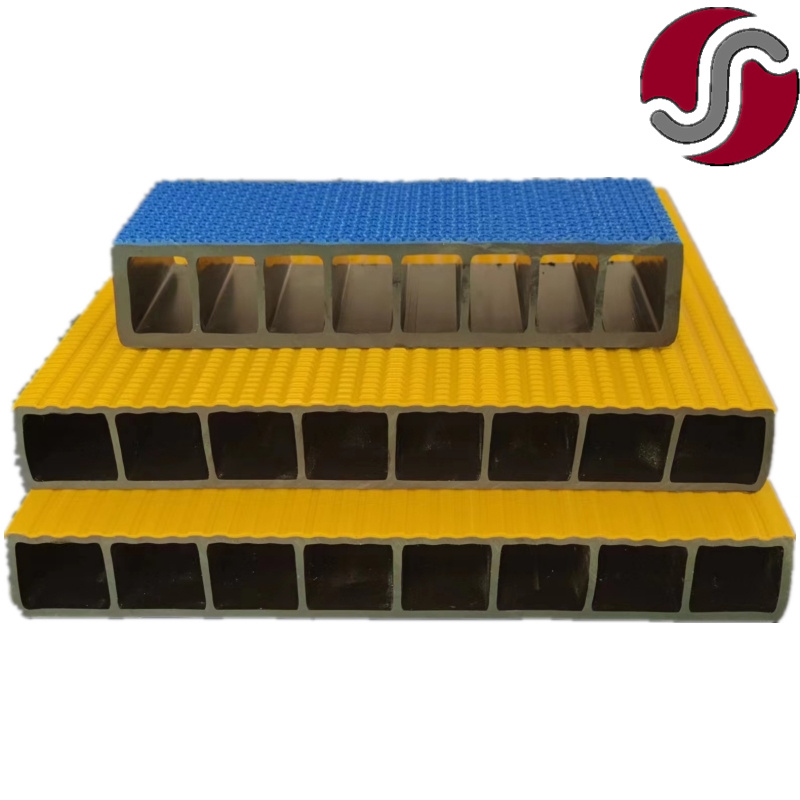

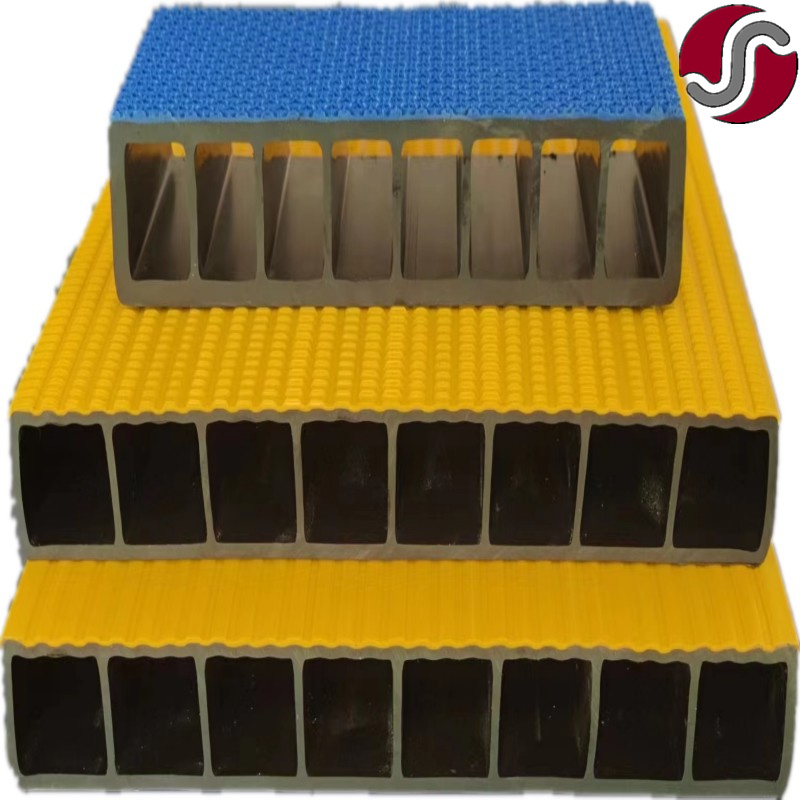

PE Fishery Raft

- Haosen

- China

- 30 working days

After-sale Service: Online technical support

Project Solution Capability: graphic design, 3D model design

Place of Origin :China

Brand : Haosen

Processing Service :Bending, Decoiling, Welding, Punching, Cutting, Anodizing, Painting, Plating, Polishing

OEM/ODM :Yes

Length :Customised

shape :customized

Colour :Customised

MOQ :Negotiable

Fabrication :Machining, CNC, sawing, milling, punching, lathing, drilling

Surface Processing :Anodize, Polish, Brush

Certificate : CE ISO9001 Europe Standard

Package : Carton

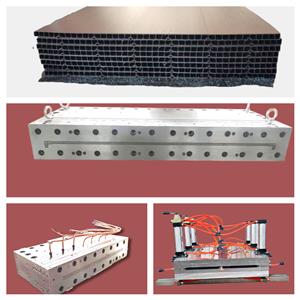

1. List of production line components

serial number | equipment | Quantity. |

1 | Automatic feeding system | 2 sets |

2 | SJ75×33 single screw extruder | 1 unit |

3 | SJ45×33 single screw extruder | 1 unit |

4 | Mould (including heating ring and sizing sleeve) | 1 set |

5 | Vacuum box | 1 unit |

6 | Spray box | 1 unit |

7 | Embossing device | 1 unit |

8 | Crawler tractor | 1 unit |

9 | Cutter | 1 unit |

10 | Bar feeder | 1 unit |

11 | Air Compressor (5.5kw) | 1 set |

12 | 2 cubic storage mixing box (with heating) + 100L color mixer | 1 set |

13 | Air compressor (with air tank) | 1 set |

14 | 20 hp chiller | 1 set |

15 | Electrical control system | 1 set |

2. Detailed description of the production line

1. Automatic feeding and drying system

Automatic feeding system |

|

Feeding method | Vacuum suction method |

Drying method | Automatic control of hot air heating |

2. Extruder

Model | SJ75×33 type |

screw |

|

--diameter | 75 mm |

-- Aspect ratio | 33:1 |

-- Material | 38 chromium-molybdenum aluminum |

-- Heat treatment | nitride |

Barrel |

|

-- Material | 38 chromium-molybdenum aluminum |

-- Heat treatment | nitride |

-- Heating control area | 5 districts |

-- Heating power | 36KW |

-- Cooling system | Air-cooled |

-- Cooling fan power | 250 watts×5 |

Gearbox |

|

-- Box material | QT200 model |

-- Gear form | Helical gears |

-- Gear material | 20 chromium-manganese-titanium |

――Heat treatment of gear surface | Tooth surface quenching |

-- Thrust bearings | High-quality bearings |

-- Lubrication system | Pressure lubrication system |

-- Cooling system | External independent cooling circulation system |

Cooling water jacket |

|

--Method | water cycle |

--Materials | Question 235 |

Drive motors |

|

--Method | AC motors |

-- Power | 110KW POWER |

3. Extruder

Model | SJ45×33 type |

screw |

|

--diameter | 45 mm |

-- Aspect ratio | 33:1 |

-- Material | 38 chromium-molybdenum aluminum |

-- Heat treatment | nitride |

Barrel |

|

-- Material | 38 chromium-molybdenum aluminum |

-- Heat treatment | nitride |

-- Heating control area | 3 districts |

-- Heating power | 18KW POWER |

Gearbox |

|

-- Box material | QT200 model |

--Format | Hard tooth surface |

-- Gear material | 20 chromium-manganese-titanium |

――Heat treatment of gear surface | Tooth surface quenching |

-- Thrust bearings | High-quality bearings |

Drive motors |

|

--Method | AC motors |

-- Power | 30KW POWER |

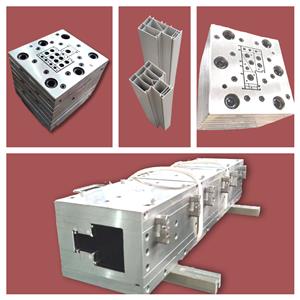

4. Mould (including heating ring and sizing sleeve)

--Method |

|

-- Heating control area | Fourth district |

-- Heating power | Max 40KW |

――Sizing sleeve material | stainless steel |

5. Vacuum box

Vacuum box |

|

-- Vacuum pumps | 5.5KW x 2 units |

-- Water pumps | 5.5KW x 1 unit |

-- Tank material | Stainless steel (where it comes into contact with water) |

-- Length | 8000 mm |

-- Itinerary | 500 mm |

6. Spray box

--Method | Spray |

-- Water pumps | 5.5KW*1 set |

vacuum pump | 5.5kw |

-- Tank material | stainless steel |

-- Length | 6000 |

7. Embossing device

--Diameter | 260 mm x 420 mm |

-- Embossed material | High-quality seamless steel rollers, surface quenching treatment, surface hardness HRC50-55 |

-- Oven | Front and rear ovens, anti-water ingress treatment |

-- Temperature control | Temperature control meter |

8 tractors

-- Traction method | Tracked |

-- Clamping method | Pneumatic and mechanical clamping |

- Number of tracks | 2 |

-- Traction motor | AC motor 4.4KW , frequency conversion control |

-- Effective track length | 2800 mm |

Track width | 600 mm |

9. a cutting machine

-- Cutting method | Cut horizontally |

-- Clamping method | Pneumatic clamping |

-- Workbench movement mode | Pneumatic system |

-- Cutting range | According to the product specification table |

-- Large-pan rotating motor | 3KW POWER |

-- Feed the knife | Pneumatic |

10. a feeding rack

-- Length | 10000 mm |

Material | Square tube welding |

11. Electrical control system

Siemens PLC control system is adopted. The inverter adopts Fuling speed regulation system, contactor Siemens Electric Group, the button and twist indicator light adopts French TE Electric Group, and other low-voltage electrical appliances use Chint or Delixi

The use of extrusion mold is also very common, if in use, the selection does not pay attention to the quality of the quality, will seriously affect the normal use of the extrusion mold, in order to make the mold get a good use, the following provides a specific way to judge the quality of the extrusion mold. First, look at the thickness of this mold, although the mold does not need to be used ...more